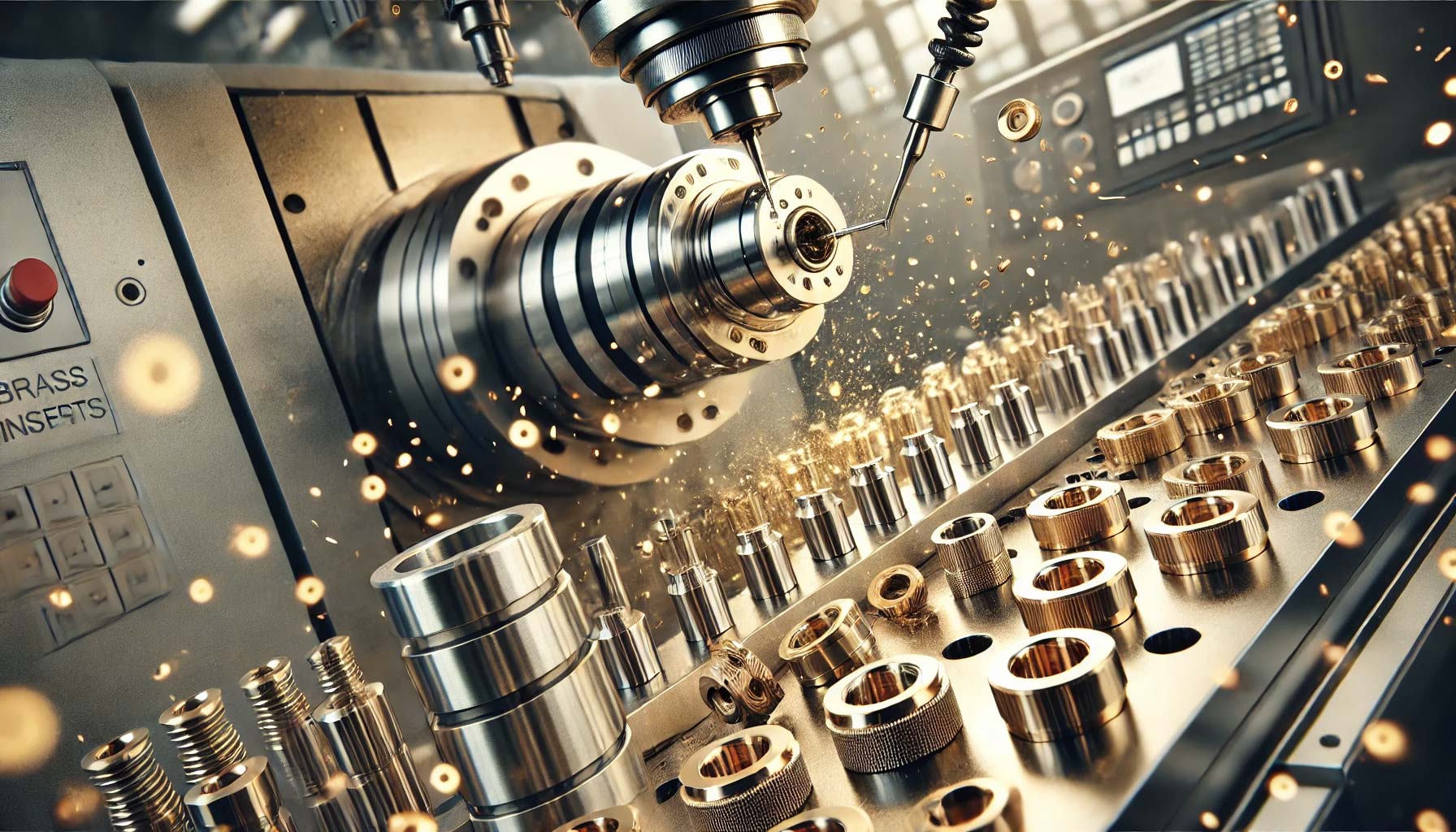

Precision engineering is the cornerstone of high-quality brass insert production. It involves meticulous attention to detail in every step of the manufacturing process, from material selection to machining and finishing. At Mark Metallurgical Factory, this commitment to precision begins with sourcing the finest raw materials and extends to utilizing state-of-the-art CNC machines to create products with unmatched accuracy.

Key Steps in the Manufacturing Process

- Material Selection: Choosing high-grade brass alloys to ensure strength, corrosion resistance, and durability.

- Machining: Employing advanced CNC technology for precise shaping and threading of inserts.

- Quality Testing: Implementing rigorous quality control measures to detect and eliminate defects.

- Custom Design: Tailoring inserts to meet unique client specifications, ensuring optimal performance in their applications.

Mark Metallurgical Factory’s expertise in these areas ensures that every brass insert produced is a testament to engineering excellence.

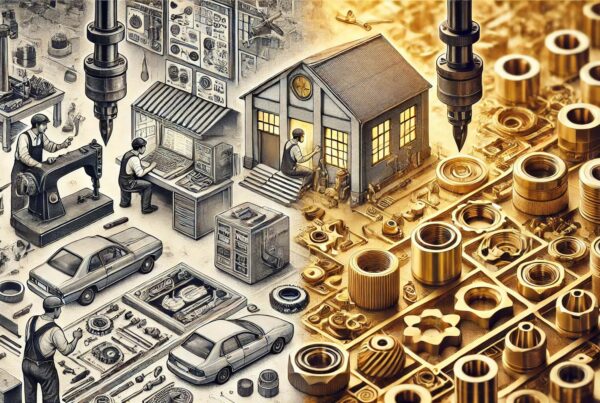

Innovation at Mark Metallurgical Factory

In its five years of operation, Mark Metallurgical Factory has built a reputation for delivering products that exceed industry standards. The company’s focus on innovation has led to the development of custom solutions for clients across the globe. Whether it’s designing inserts for high-stress environments or creating lightweight components for portable devices, the team at Mark Metallurgical consistently pushes the boundaries of what’s possible.

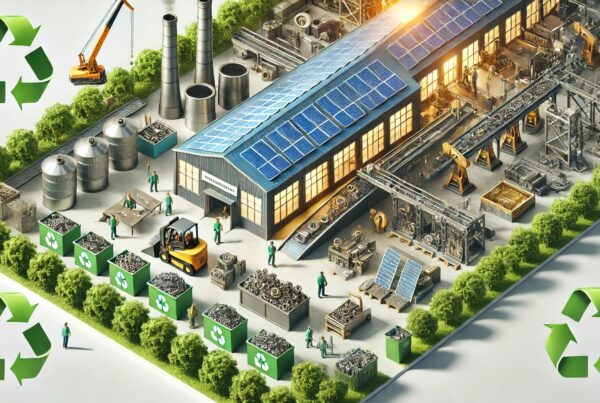

One notable aspect of Mark Metallurgical’s approach is its commitment to sustainability. By adopting eco-friendly manufacturing practices and minimizing waste, the company ensures that its operations have a positive impact on the environment while delivering superior products to clients.

The Future of Brass Inserts

As industries continue to evolve, the demand for high-quality, precision-engineered components like brass inserts will only grow. Emerging technologies such as 3D printing, IoT-enabled devices, and advanced composites are expected to create new opportunities for innovation in this field. Mark Metallurgical Factory is poised to lead this evolution, leveraging its expertise and dedication to excellence to meet the changing needs of its clients.

Conclusion

Brass inserts may be small, but their impact is enormous. From enhancing the performance of everyday products to enabling cutting-edge technologies, they are a cornerstone of modern manufacturing. Mark Metallurgical Factory’s commitment to precision engineering and innovation ensures that these humble components continue to make a big difference in industries worldwide.

By staying true to its core values of quality, precision, and sustainability, Mark Metallurgical Factory is not just manufacturing brass inserts; it is shaping the future of precision engineering.